Loading... Please wait...

Loading... Please wait...Categories

New Products

-

$381.85$305.48

-

$356.00$284.80

-

$137.10$109.68

-

$137.10$109.68

-

$174.00$139.20

Our Newsletter

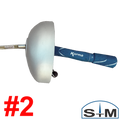

Pommel - Epee French Grip, "Melting Pommel" Version 2.0

Product Description

Newest edition of the Melting Pommel by R.W. Zehr

The newest Melting Pommel (named after Salvador Dali's "Melting Clocks") replaces the usual cylindrical epee pommels

with an ergonomic shape that fits your hand better when posting, for better comfort and less muscular stress when fencing

Extended French style epee. It maximizes hand contact with the base of the thumb and small fingers for improved control

and power. It is one of the lightest pommels available.

This third version has been redesigned for better grip, ease of installation, and strength.

- Grip is now improved with a fine-grained pebble surface, much like checkering on metal, which offers maximum

grip in any glove without needing rubber-coating. The rounded nubs of the surface will not cause additional wear of

the glove.

- Installation is a matter of mounting it on the tang using a standard internal-hex pommel nut. No shim washers are

required.

- The Melting Pommel is made of extremely strong polycarbonate thermoplastic. It has been tested with a 16 oz.

hammer on an anvil; the hammer bounces off without damage to the pommel.

Specifications:

Length: 50mm

Weight: 19g

Material: Black Polycarbonate

Competition Legality: The Melting Pommel appears to be fully legal in all US and International competition. This

assertion is based on comments by Dan DeChaine, Olympic Tournament Master Armorer and emeritus member of the

SEMI commission. Quoted here with his permission:

“There is absolutely nothing in the rules to prohibit the use of this pommel. Further, there is no need to have it approved

by the SEMI Commission as long as the total length of the pommel and grip and thickness of the guard do not exceed

20 cm.” Adding further confirmation, the Melting Pommel has passed Armory inspection at many FIE- and USAF-sanctioned

tournaments in the past five years, and has never been excluded to my knowledge.

Installation:

- The tang must protrude from the french grip a minimum of 15mm (to engage three threads), maximum 22mm.

Trim the tang if necessary. The minimum can be reduced slightly by not using the lock-washer and using a drop of

thread locker.

- Insert the supplied flat washer in the hole, followed by the lock-washer and the pommel nut.

- Do NOT ream out the hole. It is finished to 9.9mm I.D., and the nubby surface creates a press-fit on the pommel

nut for strength.

- The pommel nut will be a press-fit into the hole, for a standard 10mm pommel nut. Place the pommel nut on an

Allen wrench hex key and use it to align the pommel nut, then press it in firmly until it bottoms out.

- Screw the Palmel onto the tang, set the angle and tighten the pommel nut. The “droop” should be vertical, in the

same plane as the bend in the blade. First time use will remove excess plastic from the 6mm hole.

The Melting Pommel is warranted against breakage. If one should ever break, the manufacturer will replace it or refund

your purchase price.